The future in a beam

Enhancing the future with laser technology: El.En. fosters dynamic research and development, to shape a future of excellent innovation. With 40 years of experience rooted in our passion, we ensure a solid foundation for our customers, paving the way for tomorrow's success.

Three product series with high customization levels to meet even the most demanding production requests.

Our laser sources are developed to be versatile and with high efficiency, productivity and performance across various applications and industries.

Blade RF Self-Refilling (from 350 to 1500W) powered by NEP Technology.Blade RF Sealed-Off (from 80 to 300W)

Our compact and versatile scanning heads are designed for CO2 laser systems with precision and excellent dynamics for countless application fields.

Laser Scanning Heads 3-Axis scan headsLaser Scanning Heads 2-Axis scan heads

The new G-Series Galvanometers feature four different sizes, designed to deliver excellent performance in a wide range of applications. Equipped with an internally designed optical position sensor, they ensure high dynamic performance, accuracy, precision, reliability, and minimal thermal drift.

Scanner Components XY Galvanometer AxesScanner Components Z Axes motors

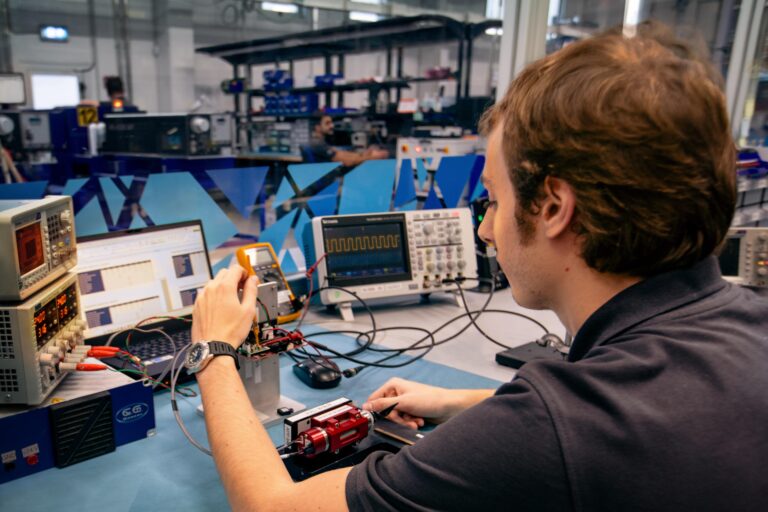

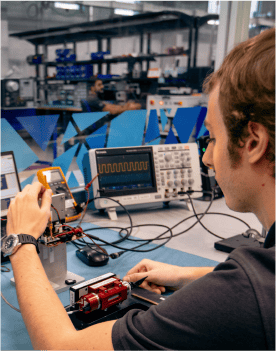

Every day we work sinergically with our customers to develop cutting-edge solutions.

Our team with its advanced skills and consolidated expertise in laser technology offers comprehensive support to customers throughout the entire process, from design to installation. Innovation and easy integration set us apart. Our technical experts and R&D team provide you with cutting-edge solutions, from start-up to post-sales.

Our Technical Support department works diligently to understand the needs of our partners and manage each request effectively and promptly.

Technical expertise, spare parts availability and timely intervention guarantee efficient production processes. Internal design and production, combined with passionate and qualified teams, are the key to our success. Global coverage ensures user and integrator satisfaction worldwide.